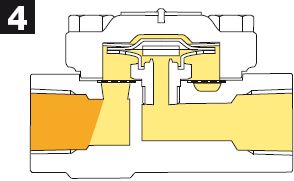

Balanced Pressure Thermostatic Steam Traps are equipped with a capsule element, which controls the discharge of condensate depending on the temperature. The capsule contains a special liquid, whose saturation temperature at a given pressure is always lower than that of the water. It ensures a very accurate functioning of the steam trap and is self-adjusting.

Series D MIYAWAKI steam traps can be delivered with 3 different capsule types:

|

The discharge characteristic follows the saturation curve independent from pressure changes and the condensate load.

Features

|

Suitable for:

| Light to medium condensate loads: steam tracing, steam main drips, small heat exchangers, unit heaters, steam heating coils and many other applications in the petrochemical, chemical, textile, food, pharmaceutical and other industries. |

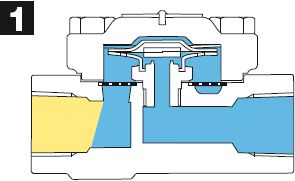

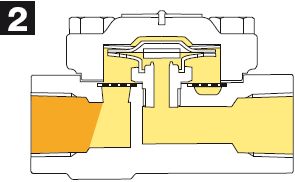

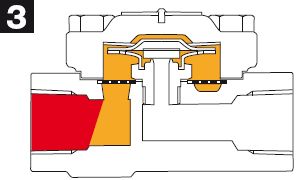

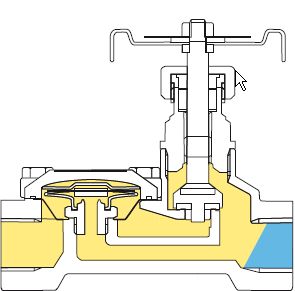

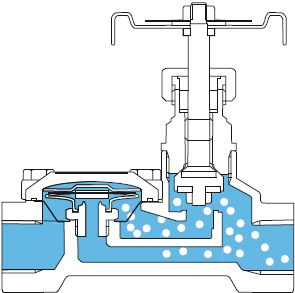

Operating principle:

Operating principle of DV1 when using the bypass valve:

When the handle is turned in the direction indicated by the BLOW arrow on the nameplate (counterclockwise), the bypass valve will open, a bypass circuit will be formed inside the trap, and a large volume of air and condensate can be discharged quickly. Scale that has accumulated in the screen can also be blown out.