| MIYAWAKI’s internationally patented SCCV-System has proven its high reliability and effectiveness during almost three decades. Many thousands of steam traps equipped with this technology have proven enormous advantages for our customers: | ||||

Download | ||||

Basic Principle of the SCCV – System

“Free Floating” of the valve inside the valve holder – thereby precise closing of the valve in the center of the seat.

A spring and a spring plate inside the control chamber absorb and soften the movement of the valve into the seat.

The upstream valve/seat design and the valve lift are designed in such a way that the valve will be closed by the flow of the condensate.

Flexible adjustment to various types

Intensive research and development activities over many years have enabled MIYAWAKI to incorporate the SCCV-System in various types of steam traps. Thus it became possible to adopt the SCCV-System not only to Bimetal steam traps, but also to Inverted bucket and Float type steam traps.

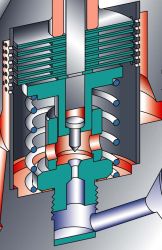

Inverted Bucket Steam Traps

Series ES

The valve holder is fixed to a specially developed “Super-Lever”. The valve is “free floating” inside the valve holder. Thus the control space inside the valve holder decreases the force toward the seat caused by the movement of the bucket. The valve will close softly and exactly in the center of the seat.

Ball Float Steam Trap

Series G11N / G12N

The valve (ball) lies inside a valve holder, which is directly connected through a lever with the float. By installing a spring inside the valve holder the movement of the float and the forces caused by it will not be directly transferred to the valve. This will increase the service life of the sealing surfaces.

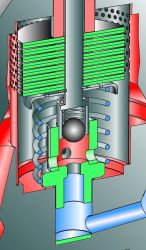

Inverted Bucket Steam Traps

Series ER

The SCCV-System is part of a “Double Valve Unit” which is operating on the basis of the pressure difference inside the unit. The trap is thus characterized by extended life of the valve assembly and a greater condensate discharge per body size when compared to conventional inverted bucket steam traps.

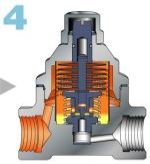

Bimetallic Temperature Control Steam Traps

Series TB7

The bimetal unit including the valve are guided inside the body. A spring reduces the force caused by the deflection of the bimetals which move the valve toward the seat. The guiding of the valve within the seat and the lift of the valve are designed in such a way that the valve will close very smoothly in the center of the seat.

The use of the SCCV-System for Temperature Control Steam Traps Models TB7

When condensate with higher temperature (near to set temperature) flows in, the bimetal discs are curved even more and , at the same time, the valve shaft moves down and the valve holder closes the holes in the guide partially.

The amount of condensate being discharged is reduced quickly. This prolongs the time that the hot condensate stays near the bimetal discs and the heat of the condensate is transferred to the bimetals much more effectively.

In case of very low condensate flow, the holes in the guide are closed completely by the valve holder and the valve will close precisely in the center of the seat. Normally, the trap is filled with hot condensate and the operation will rest in the state shown in figure 3. Condensate will be discharged continuously.